Beneath Pandora’s striking jewellery and impactful storytelling lie layers of exquisite craftsmanship and an unwavering commitment to sustainability. We travel to Thailand – the Danish brand’s second home – where its pieces come to life, to experience the artisanship firsthand and discover the responsibility that defines the company

“If you want to know and appreciate Pandora, you have to come to Thailand,” says Jeerasage Puranasamriddhi, chief supply officer of Pandora, to a group of journalists and influencers gathered at the entrance of the beloved Danish jewellery brand’s Crafting Facilities, tucked away in the lush, tropical surroundings of Lamphun, a quaint town roughly an hour from Chiang Mai in northern Thailand.

We’ve arrived from all corners of the globe for a rare glimpse into the heart and soul of Pandora, whose pulse beats between Copenhagen – the brand’s birthplace and home to its headquarters and design team – and Thailand, where the jewellery comes to life through exquisite craftsmanship, from the Innovation Centre in Bangkok to the Crafting Facilities.

We’re met with warm smiles and the sweet scent of traditional Thai malai flower garlands, delicately placed on our wrists. Ahead of us stretches a sprawling, bracelet-shaped white building – a bustling hub for 4,000 skilled artisans.

Jeerasage Puranasamriddhi, chief supply officer of Pandora, welcoming us to the Crafting Facilities. Photo: Sofi Adams

The traditional Thai malai flower garlands, placed on our wrists upon arrival and symbolising respect and luck. Photo: Marco Bahler

“Are you familiar with the story behind Thailand and Pandora?” asks Berta de Pablos-Barbier, the chief marketing officer of Pandora, as we’re welcomed into the lofty halls of the Crafting Facilities, framed by expansive windows offering peeks into the workstations, or ‘cells’, where rows of burgundy-clad artisans sit intensely focused, making the jewellery by hand.

It all traces back to the founders, Danish goldsmith Per Enevoldsen and his then-wife, Winnie Enevoldsen, who opened a brick-and-mortar jewellery shop, then called Goldsmedien 108, in Copenhagen in 1982. “The couple set out to challenge how jewellery was sold and purchased. They felt that the industry was very closed and that it was difficult to access,” de Pablos-Barbier explains. “They wanted to democratise jewellery, so that everyone could own a piece of beauty.”

The lush surroundings of the Crafting Facilities. Photo: Sofi Adams

Mads Twomey-Madsen, Pandora’s SVP of global communications and sustainability. Photo: Marco Bahler

At the time, the pair weren’t making their own jewellery yet. But during their trips to Thailand to source pieces for their shop, they were struck by the country’s masterful artisanship and captivated by its rich jewellery-making heritage. After a few years of selling imported pieces, the duo decided to start designing their own bijoux. By 1989, Pandora had established itself in Bangkok on the very premises where the Innovation Centre stands today and has fostered a close relationship with Thailand ever since.

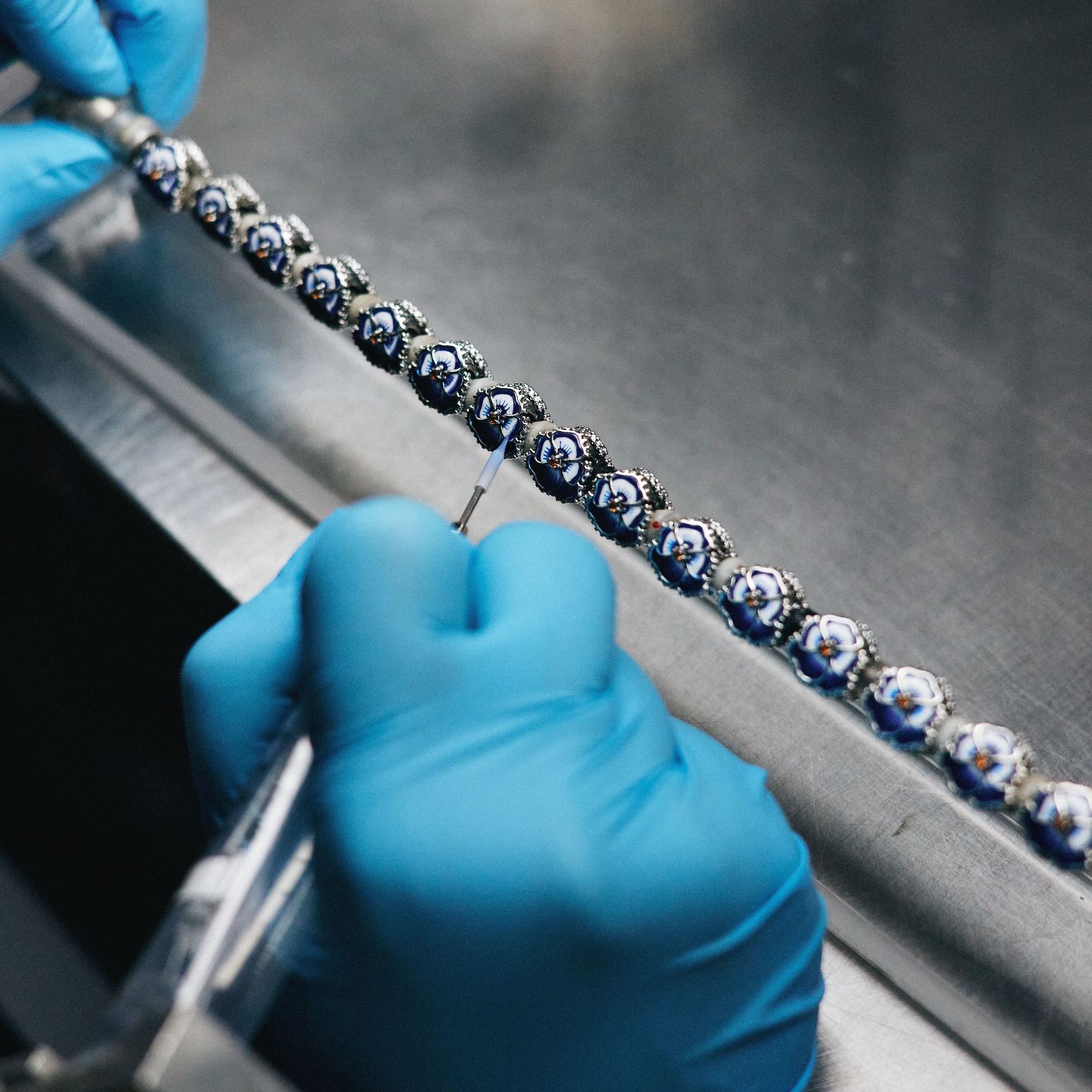

While its customisable ‘Moments’ charm bracelets earned Pandora its initial global success in the early 2000s (and remain cherished today), the company now proudly holds the title of the largest jewellery brand in the world, with a presence in over 100 countries and an impressive 113 million pieces of jewellery sold in 2024. Each piece is meticulously handmade in Lamphun and Bangkok, where every artisan goes through months – even years – of training and gains expertise in their dedicated field, whether stone setting, enamelling, or shaping the recycled Murano glass.

If you want to know and appreciate Pandora, you have to come to Thailand

Jeerasage Puranasamriddhi, chief supply officer of Pandora

At the Crafting Facilities in Lamphun. Photo: Sofi Adams

Photo: Sofi Adams

Photo: Sofi Adams

To put things in perspective: the Crafting Facilities, which opened in 2017, produces 900,000 pieces of jewellery a week, with some requiring over 20 steps to complete. Meanwhile, at the Innovation Centre – which we were the very first to be granted access to – much of the product development takes place: from creating CADs (intricate 3D models of the jewellery) based on the mood boards received from creative directors Francesco Terzo and A. Filippo Ficarelli, and dreaming up new colours and finishes, to quality control, where the jewellery undergoes a range of tests, including impact trials on various surfaces and even exposure to artificial sweat. Having seen it firsthand, the level of craft, effort, innovation and passion poured into every part of the operations – with a constant drive to improve – is truly remarkable.

At the Innovation Centre in Bangkok. Photo: Sofi Adams

With the title of the world’s largest jewellery brand comes great responsibility – particularly when it comes to protecting the health of our planet. In the past few years, Pandora has significantly accelerated its sustainability measures, most notably by introducing lab-grown diamonds in 2022 and harnessing solely 100 per cent recycled gold and silver as of 2024.

“It [sustainability] has been in the DNA of the company since the very beginning,” says Mads Twomey-Madsen, Pandora’s SVP of global communications and sustainability, referring to the values and business approach the founders embedded decades ago. To become “the leader in sustainability”, the company dove straight into the deep end with the switch to recycled precious metals – a transition that took five years of devoted work across the organisation and its supply chains.

Way back when the founders were figuring out where to start, Thailand was the natural place – and then it just became clear that this is where the company belongs

Mads Twomey-Madsen, SVP of global communications and sustainability at Pandora

The shift matters: By using recycled silver instead of mined silver, the company saves as much as two-thirds of the CO₂ emissions. In fact, Twomey-Madsen notes that if the whole jewellery industry only used recycled silver and gold, it could save a staggering 53 million tonnes of CO₂ emissions. “That’s actually the same as all the emissions from New York City,” he says.

Pandora’s iconic ‘Moments’ collection, featuring eye-catching charms to personalise necklaces and bracelets, was first introduced in 2000 and brought major global success to the brand. Photo: Sofi Adams

Photo: Sofi Adams

Then there are the lab-grown diamonds, which also deliver a substantial environmental benefit – while being just as authentic and striking as their mined counterparts, yet more accessible, perfectly aligning with the founders’ mission of democratising jewellery. “If we create a lab-grown diamond instead of mining it from the ground, we save 95 per cent of the CO₂ emissions,” Twomey-Madsen continues. “The beauty of the lab-grown diamond is it’s cheaper for consumers and it’s cheaper for the planet – oftentimes, those two things don’t necessarily go hand in hand.”

But Pandora’s commitment to eco-consciousness doesn’t stop at materials. All of its operations are powered by 100 per cent renewable electricity, while its cutting-edge Thailand facilities, built to LEED (Leadership in Energy and Environmental Design) standards, are among the greenest in the industry. In Lamphun, 99,6 per cent of waste products from the jewellery manufacturing process is recycled, reused and repurposed. Rubber from the moulds gets a new life as toys, while the plaster from the casts is turned into building materials. Elsewhere, a pond cradled by the facility collects monsoon rainwater for reuse onsite. By 2040, Pandora has set an ambitious goal: to achieve net zero greenhouse gas emissions.

Photo: Sofi Adams

Photo: Sofi Adams

As our time in Thailand draws to a close, it’s easy to grasp Puranasamriddhi’s opening words – and to feel the same magic once experienced by the Enevoldsens. “I think it really is the best expression of artisanal traditions that are rooted in the culture,” Twomey-Madsen muses. “That’s why, way back when the founders were figuring out where to start, this was the natural place – and then it just became clear that this is where the company belongs.”

Today, Pandora has cultivated a connection with the country that runs deeper than business, forging strong bonds with surrounding communities – from supporting local hospitals, NGOs and temples to helping build and refurbish primary schools in rural Thailand. ‘Be Love’ may have been Pandora’s latest star-studded campaign, but its message clearly reverberates through every facet of the brand.